Understanding Diecasting: The Process and Its Functions

Understanding Diecasting: The Process and Its Functions

Blog Article

Diecasting is a highly-specialized manufacturing technique that converts hot metal into precisely-defined components through the use of high-pressure molds. This technique has become indispensable for a wide range of industries such as electronic, aerospace, automotive and other consumer goods due to its capacity to create complex forms with incredible precision and consistency. Combining the fundamentals of metals with modern engineering it provides unparalleled accuracy and precision, which makes it a cornerstone of modern manufacturing. This article delves into the complex world of diecasting by looking at its procedure, advantages in a variety of ways.

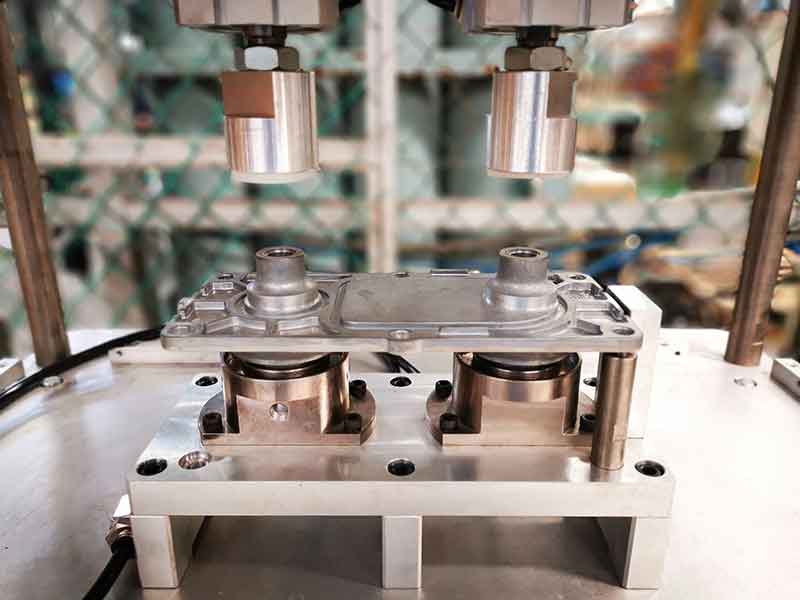

Diecasting begins by making the mold, sometimes referred to as a die, which is usually made of reinforced steel. The mold is constructed to withstand the high temperatures and pressures involved in the process. When the mold is finished to be used, the molten material, generally made of alloys of aluminum magnesium, zinc, or copper, is heated up to an liquid state, and is injected into the mold under pressure that is high. The pressure will remain constant until the metal is solidified so that the molten metal fills every part of the mold including intricate design and thin walls. When the metal has been cooled and hardened, the mold can be removed and the completed part is ejected. This procedure allows high efficiency and accuracy when making metal components.

One of the biggest advantages of diecasting is its efficiency in mass production. When dies are manufactured and shaped, they are able to produce thousands of identical parts that are identical with little variation. This level of consistency is essential for industries which require huge quantities of uniform components. Furthermore, diecasting is recognized for its high efficiency of materials. This process produces very little waste, as excess metal can be reused and recycled in subsequent casting cycles. This not only reduces material costs but also supports sustainable manufacturing by reducing waste and conserving resources. The combination of high manufacturing speed, accuracy, and material efficiency makes diecasting an attractive choice in the quest to maximize their manufacturing processes.

Diecasting is also a great method of producing pieces with outstanding mechanical characteristics. The rapid cooling of the liquid metal that is formed during the casting process creates the formation of fine grains, increasing the strength and durability of the final product. Dies makes diecast parts well-suited for projects that require reliable and high-performance. For instance, in automotive manufacturing Diecast components are utilized in the transmissions, engines and structural elements, where their weight-to-strength ratio plays a crucial role to ensure safety and efficiency of vehicles. Similar to the aerospace field diecast elements contribute to the creation of light but strong structures, crucial for improving fuel efficiency and performance. To gather new information kindly check out Senadiecasting

Diecasting's versatility extends to its wide range of applications across different sectors. For instance, in the automobile industry Diecast components play an integral role in the creation of motors, transmissions and structural parts. They contribute to the production of lighter, more fuel-efficient vehicles. Within the electronics industry the use of diecasting can be used for the production of heat sinks, connectors, housings, and other components, ensuring optimal thermal management and durability for electronic devices. The industry of consumer goods benefits from diecasting, with applications ranging from household appliances to power tools and toys. Diecasting's flexibility to various metals as well as its capability to manufacture parts with intricate patterns make it ideal for various types of applications. Each benefiting from the unique advantages diecasting has to offer.

Diecasting is an essential manufacturing process that brings together accuracy, precision and versatility. Its ability to produce sophisticated, high-quality parts with outstanding mechanical properties make it indispensable to many sectors. Diecasting's efficiency when it comes to mass production, with the material and cost benefits, underscores its value for modern manufacturing. In the era of high-performance and reliable parts continues to grow, diecasting will remain an essential technology that drives innovations and supporting the manufacturing of innovative products that satisfy the ever-changing demands of the market. By its continual expansion and development diecasting illustrates the interaction between engineering as well as manufacturing experience, strengthening its position in the future of manufacturing.